How do we better produce food in the quality and quantity needed to feed the world?

Horticultural lighting offers an innovative way of producing food in a controlled environment, often close to large markets in urban centers. Precise LED light and advanced sensing solutions provide new possibilities for growing food in a smart, easy and sustainable way. They allow us to adapt to the needs of different plants, monitor their growth, optimize harvests, minimize fertilizer use and reduce energy costs. In fact, LED- and sensor-based horticulture solutions demonstrate how our lives can be improved by technology.

Efficiency is vital for horticulture luminaires. High efficiency enables low energy consumption and a faster amortization of the luminaire due to the lower electricity bill. Key to luminaire optimization are highly efficient Hyper Red LEDs with a wavelength of 660 nm.

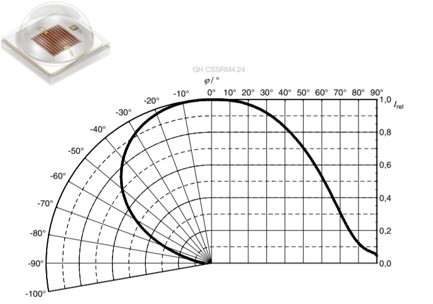

The latest generation of the OSLON Square Hyper Red is the GH CSSRM5.24. With a typical radiant flux of 1064 mW and a typical wall plug efficiency (WPE) of 76%* at 700 mA driving current, it outperforms its predecessor, the GH CSSRM4.24, which has a typical radiant flux of 1045 mW and a typical WPE of 74%*.

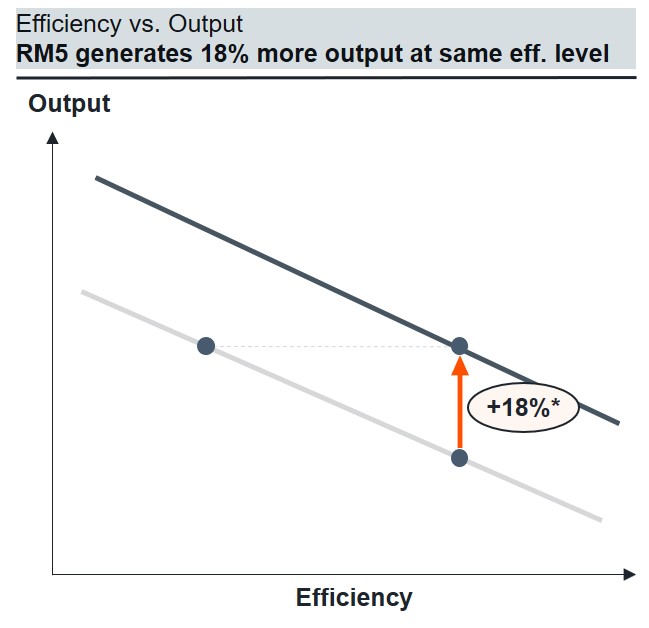

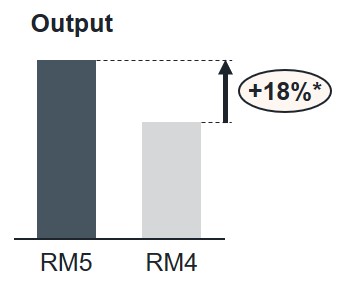

Option 1: fixing the efficiency level

The first option is to fix the efficiency level of the system. The GH CSSRM5.24 can generate 18%* more output at the same efficiency level compared to the previous generation GH CSSRM4.24.

This means that the fixture will simply have a higher performance in terms of photosynthetic photon flux (PPF) when using the latest generation of the OSLON Square Hyper Red. This will help to generate more biomass and shorten the harvest cycles – an important factor for growers.

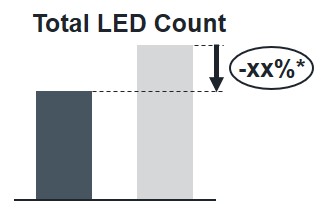

An alternative is to fix the efficiency and the performance output level of the system. That means the number of LEDs can be reduced with the more efficient GH CSSRM5.24. Depending on the application case, the LED count can be reduced by a double-digit percentage and consequently the system costs can be reduced as well.

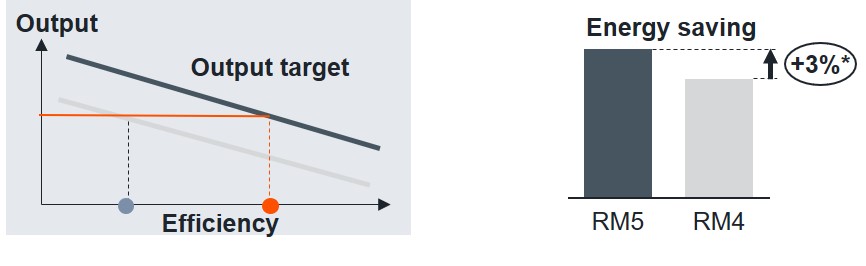

Option 2: keep the output constant

The second option is to keep the output of the fixture constant. In this way, the fixture using the new generation will be more efficient and lead to a greater energy saving.

Option 3: optimize system output and efficiency with the new generation

The third option is to keep the LED number and the driving current constant, leading to an increase in both output and efficiency for the system when using the new LED generation. This leads to more biomass due to the increased output, and a faster amortization due to the increased efficiency.

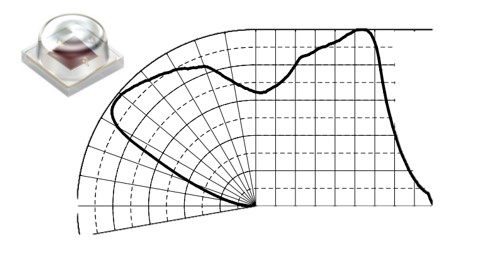

Batwing lens design for wider and more uniform radiation of light

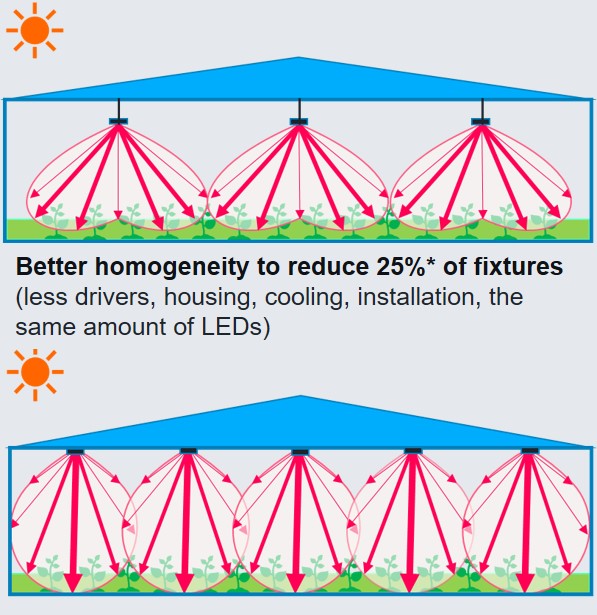

A new member of the ams OSRAM horticulture LED family is the OSLON Square with Batwing lens. This new primary lens design is available in all relevant colors for horticulture lighting, like Hyper Red, Deep Blue, Far Red and Horti White. The Batwing lens provides a wider radiation characteristic than the standard lens. A typical application case for luminaires with a wider radiation pattern are high-wire greenhouses.

With a broader radiation pattern, a better uniformity of the photosynthetic photon flux density (PPFD) at plant level can be achieved. This advantage can be used to reduce the number of luminaires, keeping the PPFD uniformity at the same or even higher level compared to luminaires with a standard lens version. The benefit is that there is potential to reduce the total investment costs in a greenhouse by saving assembly and material costs due to the reduced number of luminaires.

Quantum sensing via spectral sensors – knowing is good, monitoring is better

Via the AS7343 spectral sensor, it is possible to measure relevant horticulture lighting parameters – like PAR, PPFD, PPE – continuously to enable automatic LED balancing.

In greenhouses, for example, if the light conditions change due to weather, clouds, or even smudged windows, finding the ideal balance between LED light and sunlight can be a challenge.

Using spectral sensing, the mix is actively measured to enable daylight harvesting and to save energy. With the known PPFD or PPE values required by the plants, the setup can be as simple as dimming lights, by measuring the exact values at the plant level and adjusting the lighting accordingly.

Furthermore, with the aging of luminaries, and with exposure to sometimes extreme weather conditions (e.g. very cold temperature), the lighting output as specified by the luminaries cannot be guaranteed. This is one additional reason why monitoring of light conditions close to the plants is imperative to ensure proper feedback loop to the control system which has the task to care for optimal delivery of light energy for efficient plant growth.

Why ams OSRAM?

ams OSRAM is a global leader in professional LED horticulture lighting and sensing. Optimized LEDs and spectral sensors from our extensive product portfolio enable superior plant growth – whatever the growing recipe. Highest efficiency luminaires minimize energy consumption, which is essential at a time of exploding energy costs and energy-saving constraints. Best-in-class LED illumination uniformity means luminaires can be closer to the crops to potentially save additional energy compared to traditional luminaires with secondary optics. The lowest possible overall system cost results from the highest power LEDs which reduces the number of LEDs required per square meter – supported by unmatched illumination uniformity for luminaires without need for secondary optics, and long-life performance. Our LEDs provide maximum design flexibility at optimum efficacy as the overdrive capability is up to twice the nominal power class with a low thermal resistance.

Our extensive product portfolio makes ams OSRAM the customer’s partner of choice. We combine pioneering wavelength-optimized LEDs over the relevant color spectrum with spectral sensing technologies for cutting-edge growth stimulation and precise condition monitoring. Our extensive emitter portfolio for addressing professional top-, inter-lighting and vertical farming applications covers all the key growth-optimizing wavelengths and radiation-angle options needed for all types of plants and flowers. High power LED devices enable small form factors for the luminaires and allow for less shadowing.

Our spectral sensing technology enables real-time monitoring of total illumination at the plants to manage adaptive lighting recipes for growth while accounting for sunlight influences in greenhouses. Chip-scale spectral sensing technology extending from the visible to the near-infrared (NIR) spectrum opens all-new arenas of condition and growth monitoring.

> Read also our press release about New OSLON™ Optimal LEDs

*All percentages are approximate values