Smooth traffic flow through automatic barriers: infrared LED optimizes license plate recognition

Osram Opto Semiconductors is expanding its offering of high-power infrared LEDs for illumination solutions to include a new wavelength (810 nm). This development will benefit camera systems, such as those used to read license plates. They can use this additional wavelength to improve image contrast making it easier to read patterns from recorded images. Moreover, camera sensors have higher sensitivity at 810 nm. At the same optical output, the new device therefore extends the range of camera systems as compared to 850 nm.

With the SFH 4703AS, Osram Opto Semiconductors is adding the wavelength 810 nanometer (nm) to its Oslon product family for infrared illumination. These devices are primarily used in camera systems that illuminate an observed object with infrared light to ensure high image quality at all times.

Greater image contrast for easier analysis

The newly available wavelength is particularly advantageous for applications requiring superior image contrast. Wavelengths of 850 nm and 940 nm typically used in today have difficulty creating high-contrast images of certain color combinations.

Camera systems supporting automatic license plate recognition at toll stations or entrances to parking garages are a perfect example. The SFH 4703AS gives these cameras higher-contrast images for many types of license plates, making it easier to retrieve the license plate numbers. As a result, automated barriers function more smoothly, reducing waiting times for drivers. And other camera applications also stand to benefit from the new component, such as traffic monitoring and closed-circuit television (CCTV) systems.

Increased range – same optical output

This new wavelength comes with the added bonus that the spectral sensitivity of typical camera sensors is higher in this range than it is for 850 and 940 nm. Using a light source with the same optical output, an 810 nm system will achieve a greater detection distance than was previously possible. Alternatively, this also allows designers to reduce the number of components if they wish to maintain the same range. However, designers should bear in mind that humans do perceive infrared light as a mild red glow, and this is stronger at 810 nm than at 850 nm.

High optical performance – proven package

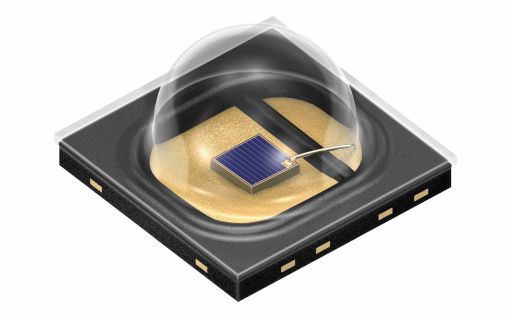

Osram Opto Semiconductors today provides 810 nm emitters for iris scanners in mobile devices. For the SFH 4703AS, developers mounted the highly efficient chip manufactured in nanostack technology in the tried-and-tested Oslon package for illumination applications. At 1 amp current, the emitter generates 1 watts optical power. The beam angle of +-45° allows for broad illumination, with a resulting radiant intensity of 630 milliwatts per steradian (mW/sr) at 1A. The component measures 3.85 by 3.85 mm, and is 2.29 mm high including the lens.

With this new device, designers can now choose from mutually compatible emitters in three different wavelengths. These can be combined within a single illumination unit or used to convert existing systems to another spectral range without the need for layout changes.

ABOUT OSRAM

OSRAM, based in Munich, is a globally leading lighting manufacturer with a history dating back about 100 years. The product portfolio includes high-tech applications based on semiconductor technology such as infrared or laser lighting. The products are used in highly diverse applications ranging from virtual reality, autonomous driving or mobile phones to smart and connected lighting solutions in buildings and cities. In automotive lighting, the company is the global market and technology leader. Based on continuing operations (excluding Ledvance), OSRAM had around 24,600 employees worldwide at the end of fiscal 2016 (September 30) and generated revenue of almost €3.8 billion in that fiscal year. The company is listed on the stock exchanges in Frankfurt and Munich (ISIN: DE000LED4000; WKN: LED400; trading symbol: OSR). Additional information can be found at www.osram.com.