Technology

Smart sensors powering AI and ML innovation

ams OSRAM’s ultra-precision sensors deliver high-quality, real-time data essential for artificial intelligence (AI) and machine learning (ML) systems. Optimized for edge AI, our sensors accelerate model training and enhance real-time analytics, accuracy, and system efficiency – while reducing complexity to enable more responsive applications.

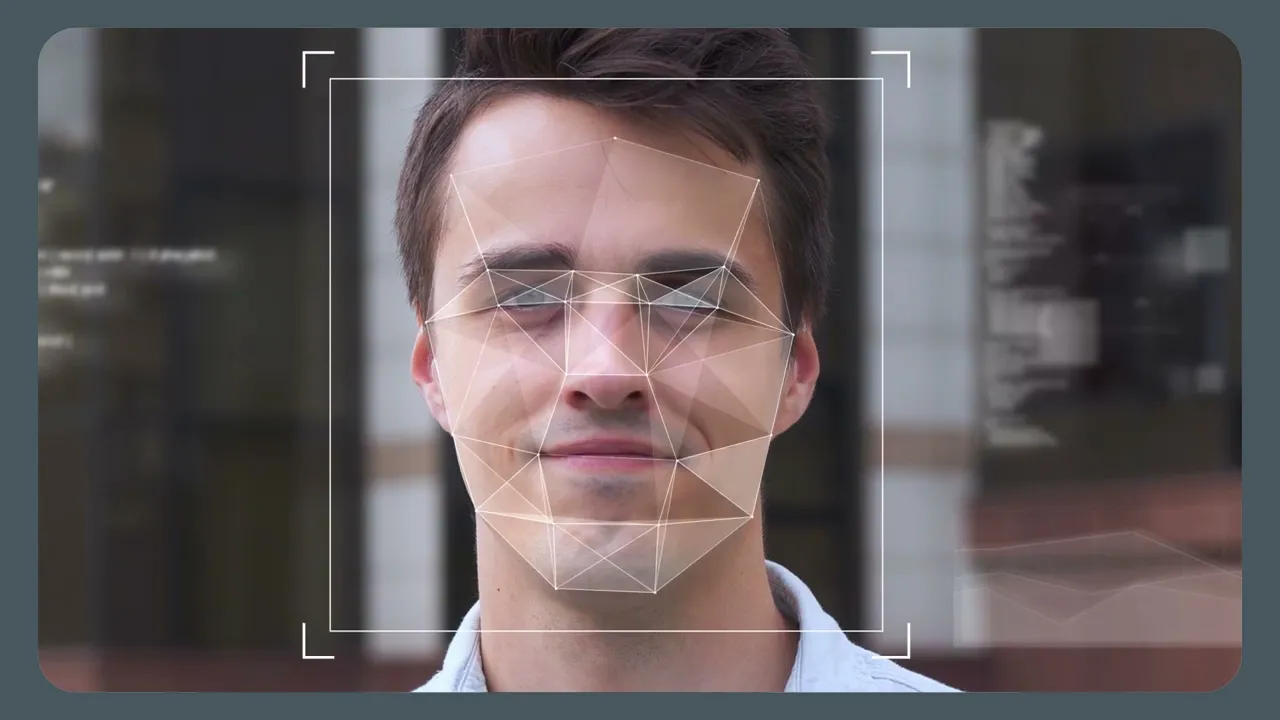

From dToF sensors with multi-zone depth map processing to image sensors, sensitive light and spectral sensors, highest precision position or digital temperate sensors, our portfolio is designed for edge applications across industries – from healthcare and wearables to robotics, smart appliances, industrial automation and automotive. Our sensors empower next-generation AI systems with scalable, intelligent data mining: they enable proper assessment of health state, support advanced eye, face and hand tracking functions or unlock new capabilities for spectroscopic analyses – just a few examples where our sensors make solutions smarter, faster, and more responsive.

Full-Service Foundry

Are you designing cutting-edge analog/mixed-signal ICs for applications requiring robustness, cost efficiency, and lower power consumption? Partner with ams OSRAM foundry experts for comprehensive IC solutions from initial design support to guaranteed long-term supply. With four decades of expertise in automotive, industrial, medical, and consumer applications, we deliver high-quality European CMOS manufacturing, reliable global sourcing, and advanced technologies such as Through Silicon Vias (TSV), optical filters, and die stitching.

As your trusted partner, we specialize in innovative IC manufacturing and automotive-certified operations, ensuring first-time-right designs, supporting multiple process and voltage options.

ASICs

We have been creating unique ASIC (Application Specific Integrated Circuit) solutions in partnership with customers for over 30 years.

We enable our partners to create highly differentiated products that are smarter, safer, easier to use and more eco-friendly.

ams OSRAM chip-packaging technologies

Chip-packaging technologies developed by ams OSRAM help our state-of-the-art optical devices and sensor products to achieve extreme high precision, low noise performance and reduced system costs.

Advanced packaging technologies from ams OSRAM include:

-

Wafer-level optics, which enable the precise fabrication of lenses for miniature light sources and detectors

-

Through-silicon vias, which radically reduce the height of an optical IC package and eliminate the need for wire bonds

-

System-in-package (SiP) technology – ams OSRAM integrates complete sensor assemblies into a single SiP to save space and eliminate a board assembly process for customers

-

Stacked dual die – wherever reliability is a must, ams OSRAM offers fully redundant solutions with two of the same sensor dies in a single IC package.

Position sensing technologies

Unique technology developed by ams OSRAM protects position sensors from interfering magnetic stray fields and reduces angle error so that – despite often harsh environments – they operate with accuracy and reliability.

Stray-field immunity: ams OSRAM position sensors feature a unique technology which protects them against interference from magnetic stray fields. The sensors overachieve ISO 11452-8, which specifies tests for the electromagnetic immunity of electronic components to magnetic fields for passenger cars and commercial vehicles regardless of the propulsion system.

Dynamic angle error compensation (DAEC™): DAEC™ is a revolutionary recent technology that yields almost zero output latency and ultra-fast refresh rates in high-speed motor control systems.

Coil design: the inductive position sensor technology is based on measuring the coupling between the coil (excitation and receiver coil) via rotating target. Due to its flexibility, easy adaption and low overall system costs, inductive position sensing acts as the perfect resolver replacement and can be used for on-axis as well off-axis applications.

PSI5 interface: PSI5 is a standard bus which enables communication between devices in an automotive system over a twisted-pair cable.

Capacitive sensing

Capacitive sensing is a widely used technology in human presence detection, fluid-level sensing or hands on detection for autonomous driving. It works on the principle of capacitance: charge accumulates in the gap between two sheets of metal, or ‘electrodes’, when a voltage is applied to one electrode. The amount of charge which accumulates depends on a property, the ‘permittivity’, of the material between the electrodes.

At the heart of the capacitive sensor measurement system is a type of capacitive sensing technology called I/Q demodulation. This method measures the resistive as well as the capacitive element of a system’s impedance. The effect of this is that, unlike other methods for capacitive sensing, it works reliably even in difficult conditions, and is sensitive to small changes in resistance.

CMOS imaging

ams OSRAM continuously develops new technology to improve the performance of its CMOS image sensors. These technology improvements support both custom CMOS image sensor developments and standard, off-the-shelf CMOS image sensor products.

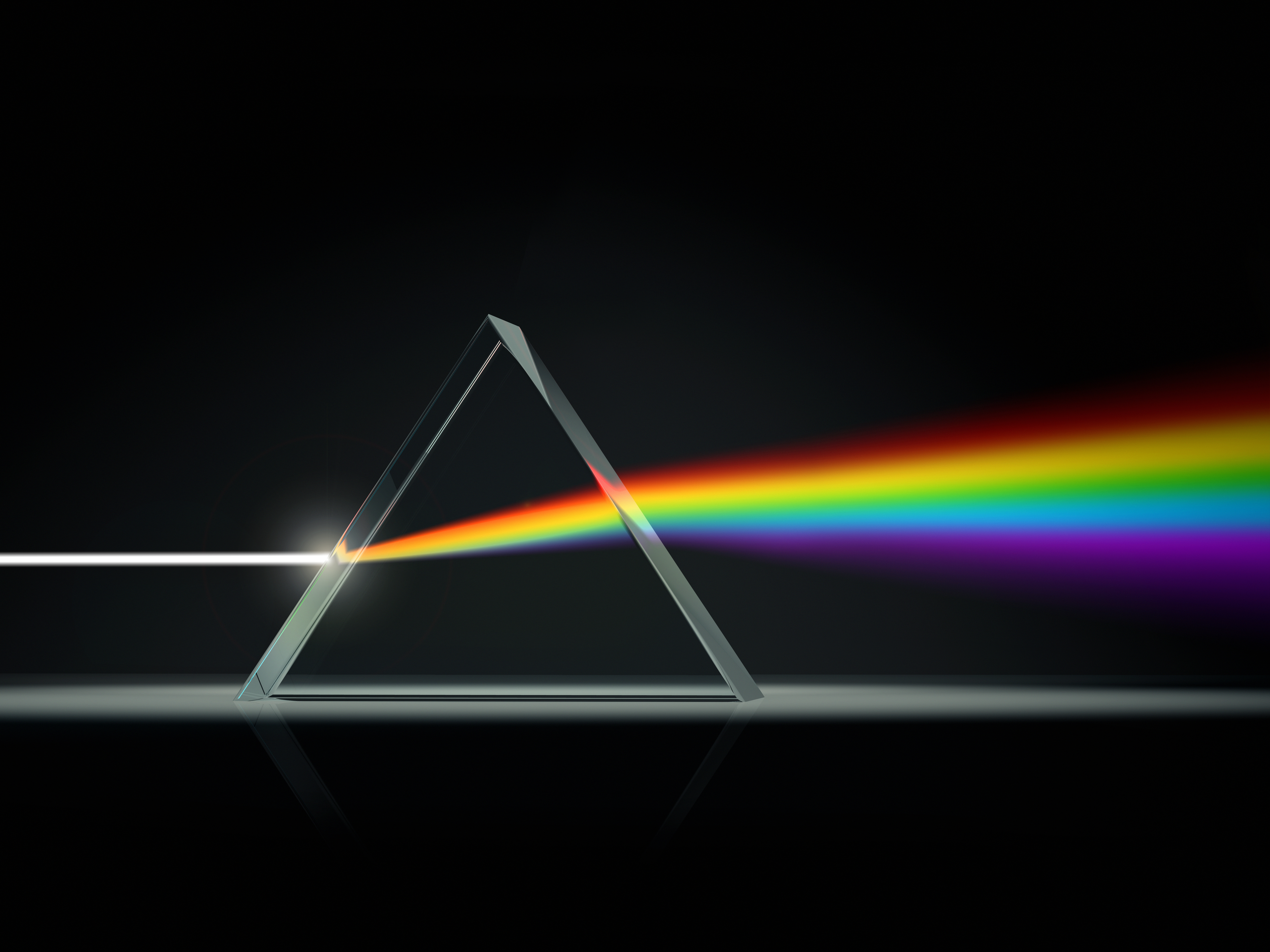

Spectral sensing

By shining light on or through objects and by looking at the reflected or transmitted spectrum, a sensor system can detect or classify what it is looking at.

Advantages of ams OSRAM spectral sensing technology:

- Interference filter technology for durability and spectral stability over time and temperature

- In-house filter manufacturing and testing capability

- In-house module design and manufacturing capability including

- Detectors

- Light source

- Light path

- Optics

VCSELs for flexibility and reliability

Vertical-cavity surface-emitting lasers (VCSELs) have various advantages over other types of lasers. These include:

-

surface emission, which offers design flexibility in addressable arrays

-

low temperature dependence of the lasing wavelength

-

superior reliability

-

a wafer-level manufacturing process

ams OSRAM VCSEL technology includes the epitaxial structure and chip design, epitaxial growth, front- and back-end processing, packaging and advanced testing and simulations. ams OSRAM VCSELs are rated for operation at ambient temperatures as high as 150°C.

Edge-emitting lasers (EEL)

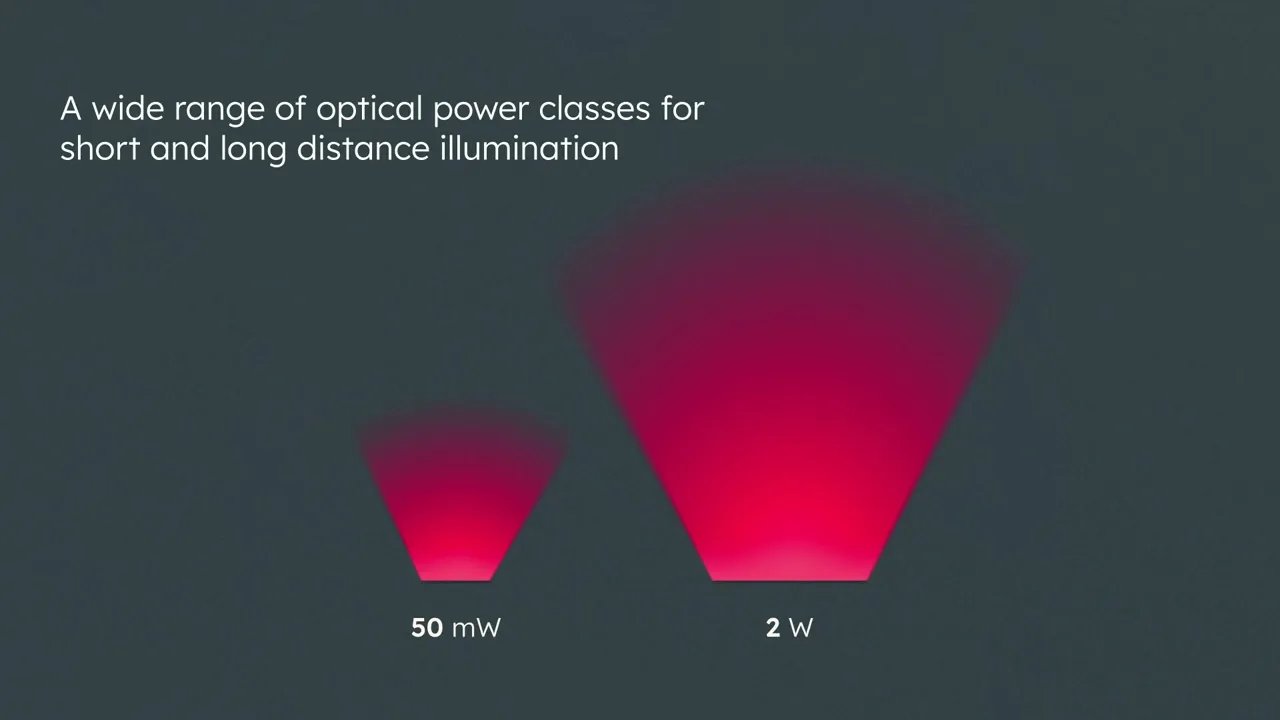

ams OSRAM leads in visible and infrared edge-emitting lasers (EEL) technology for sensing, visualization and material processing.

Edge-emitting lasers use nanostack technology (e.g.: triple-junction: three light-emitting surfaces (pn-junction) stacked one on top of the other), which has the main advantage of delivering high power within a small area (small size), making it the technology of choice for long-range LiDAR, visualization, illumination and material processing.

Infrared laser diodes for sensing (LiDAR applications) with wavelength of 905nm have the highest efficiency on the market. The laser diodes can operate with extreme short pulses (down to 2nsec), while delivering outstanding power.

Visible InGaN laser diodes for laser projection and illumination have a great optical output power at high operating temperature range. Single-mode laser diodes can operate at a higher temperature range without active cooling and have excellent efficiency, which can extend long life.

High power performance with multi-mode laser diodes are the best fit for industry and automotive applications.

> Explore our laser competence

Infrared LEDs for invisible applications

Infrared illumination plays a significant role in the broad fields of industry, automotive and consumer applications: CCTV, biometric identification, driver monitoring, machine vision to name only a few.

With a long history in developing infrared LEDs, ams OSRAM is the industry leader in this technology, offering a range of products to match the varying requirements of each application area:

-

wall-plug efficiencies well above 50%, based on ams OSRAM’s thin-film technology

-

low operation voltage and extremely high-power ratings/low thermal resistance

-

wavelengths of 850nm and 940nm

-

various beam angles

-

Single- and dual junction (stack) chips

Continuously expanding and improving the IR LED portfolio, ams OSRAM is well-positioned to remain the market leader in infrared illumination.

Depth & 3D sensing

Structured light, passive/active stereovision, integrated Time of Flight, direct Time of Flight or intensity proximity - a wide range of optical sensing techniques exist to sense distance and capture 3D scenes.

Active spectroscopy for accessible, high‑precision sensing

Spectroscopy is moving beyond labs into everyday products. This page introduces active spectroscopy—a flexible approach that uses multiple narrowband LED emitters with a broadband photodetector to capture material “signatures” for classification, quality control, and smart automation. Unlike traditional, complex laser setups, active spectroscopy leverages high‑stability ams OSRAM LEDs, sensitive photodetectors, and a precision analog frontend measurement controller to deliver reliable results at lower cost and with far greater configurability.

Active spectroscopy maximizes signal‑to‑noise by using all emitted photons per measurement, supports reflective or transmissive absorption measurements at diverse user selectable spectral configurations, and integrates cleanly with AI/ML for robust object classification.

At the heart of this solution is the Optical Measurement Kit (OMK)—a modular hardware platform for rapid spectral evaluation and prototyping. OMK lets you mix and arrange up to eight emitters and eight detectors, user configurable control sequences including automatic ambient light suppression, visualize data via a PC GUI, and iterate quickly toward the spectral setup your application needs.

TSV technology enabling high‑performance sensors for multiple industries

Through‑Silicon Via (TSV) technology is essential for building compact, highly integrated, and electrically robust sensor solutions. By routing signals vertically through the silicon, TSV shortens interconnect paths, reduces parasitic effects, and improves overall signal integrity—enabling smaller and more efficient device architectures.

What TSV enables:

- Greater design flexibility through vertical routing

- Lower‑noise signal paths

- Enhanced optical system integration

- High mechanical stability for demanding environments